The Basic Principles Of machining

Pcs and CNC machine instruments continue on to produce quickly. The pc revolution has an incredible influence on this development. From the late 1980s smaller machine shops had desktop computer systems and CNC equipment tools. Shortly just after, hobbyists, artists, and designers started acquiring CNC mills and lathes.

In existing usage, the term "machining" without the need of qualification normally indicates the normal machining procedures.

The main movement is provided by rotating the workpiece, along with the feed movement is reached by moving the reducing Device slowly in a route parallel on the axis of rotation of your workpiece.

Not known Factual Statements About machining

Ram-form mill This can confer with any mill that has a reducing head mounted on a sliding ram. The spindle can be oriented possibly vertically or horizontally. In follow most mills with rams also contain swiveling capacity, if it known as "turret" mounting. The Bridgeport configuration may be labeled as a vertical-head ram-style mill.

This method is employed for the creation and modification of furnishings, shoe lasts, brush handles, boats, golf golf equipment and even more. CNC grinding, However, takes advantage of a disc, belt or abrasive wheel to deliver automated precision product removal and surface area complete. CNC cutting contains a broader choice of Software possibilities, Even though the concluded product or service is none the considerably less precise. A cutting machine may employ laser, drinking water jet, knife, flame or plasma approaches relying on the advantages and disadvantages they supply in distinct purposes.

Box mill or column mill Very primary hobbyist bench-mounted milling equipment that characteristic a head riding up and down on the column or box way.

This contributes to a sharp reduction in—or entire elimination of—preliminary (tough-Performing) operations and to a predominance of finishing functions in machining.

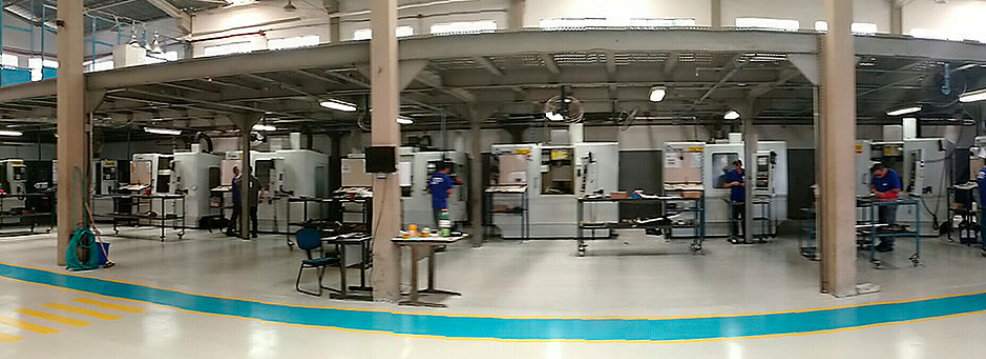

Our partners support the most up-to-date in speedy CNC machining, routing, and turning procedures, can assist a superior full article level of part complexity and provide Remarkable floor finishes. We also can device and inspect to any second drawing, often making sure you've the CNC machined areas you'll need, at-top quality and on time.

5 Essential Elements For precision machining

Milling equipment advanced with the observe of rotary filing—that's, managing a circular cutter with file-like teeth in the headstock of a lathe. Rotary filing and, later, true milling ended up made to reduce effort and time used hand-filing. The full Tale of milling device growth may well never ever be identified, because Significantly early improvement passed off in unique outlets the place couple documents ended up held for posterity.

Machining is any method by which a cutting Instrument is utilised to get rid of tiny chips of material within the workpiece (the workpiece is frequently called the "function"). To carry out the operation, relative motion is required involving the Device as well as the operate.

In turning, a chopping tool with one leading edge is utilised to eliminate material from the rotating workpiece to make a cylindrical shape.

If you use CNC machining to make a element, you'll get curved locations where conclude mills can’t produce a sharp corner.

precision machining No Further a Mystery

Even during the CNC era, a significant workpiece needing machining on multiple sides lends by itself to a horizontal machining Middle, though diesinking lends itself to a vertical a single. Substitute classifications[edit]